Alloy Enterprises Cold Plate Achieves 4,350W Cooling at Lower Flow Rate than OCP Standard

BOSTON, Oct. 09, 2025 (GLOBE NEWSWIRE) -- Alloy Enterprises today announced its advanced direct liquid cooling (DLC) cold plate technology has demonstrated the ability to cool up to 4,350 W. Alloy achieved this performance using PG25 at a 44 °C inlet temperature with a flow rate of only 4 LPM. This is 33% lower than the OCP recommended flow rate of 6 LPM for a 4 kW TDP chip, demonstrating the potential for even higher power chip cooling.

As power increases, traditional cold plate technology faces growing limitations. Most single-phase designs, such as skived fin, top out near 2,000 W. Meeting the demands of next-generation high-power chips requires a fundamentally new approach to cooling, and Alloy delivers that innovation.

These results are drawn from Alloy’s rigorous test bench, which demonstrated performance on an H100-sized geometry using standard thermal interface materials. This testing validated the cold plate’s ability to meet the demanding requirements of next-generation high-power chips under real-world conditions.

Alloy’s solution lies in its innovative microcapillary™ architecture, which dramatically shortens flow lengths, deploys massively parallel cooling channels, and distributes fresh coolant throughout the cold plate. The result is significantly lower pressure drop, reduced thermal resistance, and the ability to dissipate heat precisely at its source.

“Our cold plate technology not only reaches 4,350 W of cooling capacity, but does so at a flow rate below the OCP guideline,” said Dr. Ali Forsyth, CEO and co-founder of Alloy Enterprises. “By delivering higher performance at lower flow and pressure drop, we’re opening new thermal headroom for next-generation AI, enabling greater efficiency and scalability where conventional designs fall short.”

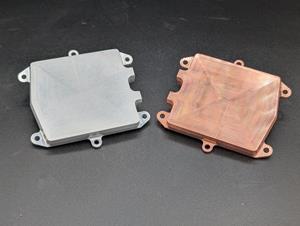

This breakthrough is enabled by Alloy’s proprietary Stack Forging™ manufacturing process, which creates single-piece, leak-tight copper and aluminum components with fully supported internal cooling features. Central to this capability is Alloy’s proprietary library of plug-and-play microgeometries, designed with unique thermal performance properties that target heat directly. These advanced microgeometries can only be manufactured via Stack Forging, delivering unprecedented cooling efficiency, lower pressure drop, and scalability for next-generation high-power computing applications.

Alloy's results position its microcapillary cold plates as a leading solution for liquid cooling. Alloy can offer better thermal performance and denser server blades by cooling GPUs, CPUs, DIMMs, SSDs, QSFPs and a variety of other peripherals to enable 100% DLC.

Meet Us at OCP Global Summit 2025

Join Alloy Enterprises at the OCP Global Summit in San Jose, October 13–16, where we will be presenting “Implications of Increased Flow Rates on Next-Generation Liquid Cooling Systems” on October 14th at 1:55 PM alongside nVent. Discover firsthand how our breakthrough DLC technology is reshaping thermal management for tomorrow’s computing platforms.

About Alloy Enterprises

Alloy Enterprises delivers high-performance thermal management components designed and manufactured in the U.S. Our patented Stack Forging™ process creates leak-tight, single-piece components with embedded microgeometries. These enable maximum heat transfer, reduced pressure drop by up to 4×, and improved thermal resistance by over 35%, dramatically lowering pumping power and energy use. Our solutions support a wide range of applications, including GPUs, CPUs, memory modules, NICs, power electronics, and semiconductor tools. Now shipping to leading data center, industrial, and military customers.

For more information, visit www.alloyenterprises.co.

Contact

Samantha Lindsay, Alloy Enterprises

sam.lindsay@alloyenterprises.co

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/b8fb8a4a-9323-4944-b4ea-4f4b9ac32b30.

Alloy's Microcapillary™ Cold Plate Technology

Alloy's monolithic cold plate features integrated microcapillary channels that enable 4,350W cooling capacity while reducing pressure drop by 4x compared to conventional designs. The single-piece construction eliminates leak points and enables efficient heat removal at the source.

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.